020 Rebuild

5th gear parts cleaned and ready to be assembled. New bearing, sync keys, sync springs, 5th bolt, and sync ring (not shown). The cap of oil is to coat the new parts with during assembly. Everything gets wet...

Install the 2 sync key springs so that they are offset 120 degrees. Be sure the bent end of the spring engages the back of the sync key....

Pop on the retaining ring that stops 5th gear from traveling to where 6th would be. Push it in until the 3 tabs click into place behind the sync keys...

Make sure you check the clearance between the sync ring and the gear face. Use a feeler gauge to check the gap as shown. The specs are listed in the Bentley for each gear.

1st & 2nd = 1.1.-1.7mm

3rd = 1.15-1.75mm

4th & 5th = 1.3-1.9mm

Wear Limit for all = 0.5mm

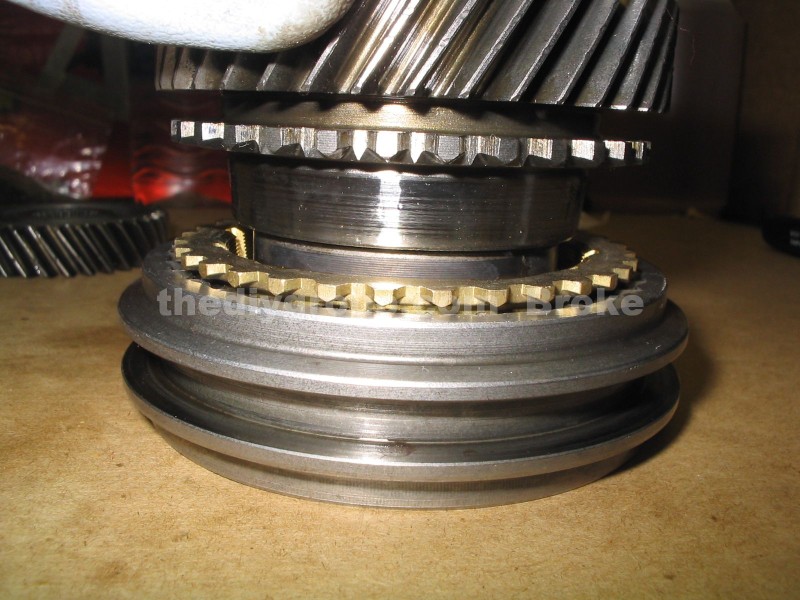

Make note of the profile of the small sync teeth that the sliding collar engages with. They should have a nice sharp tip, and no rounded sides or flat tips. Check the gear, and the sliding collar, and the sync hub itself for wear on the splines or the small teeth...

Install the sync collar as shown. Hold the 3 sync keys in with one hand, and slide the collar onto the sync hub, making sure the keys stay in place. Also install the new 5th gear needle bearing...

This is not 5th gear, but it shows how the keys are held to slide the collar onto the hub...

Drop the sync ring onto the assembly as shown, lining the notches in the ring with the 3 keys...

Install the 5th gear onto the needle bearing,

Install the thrust washer as shown, making note of the angled edge facing towards the input shaft large ball bearing...

When installing the 5th gear bolt, which should not be reused, make note of the washers angled edges, and install as shown (except the washer is UNDER the bolt head :P I needed it raised up to get a decent pic!)...

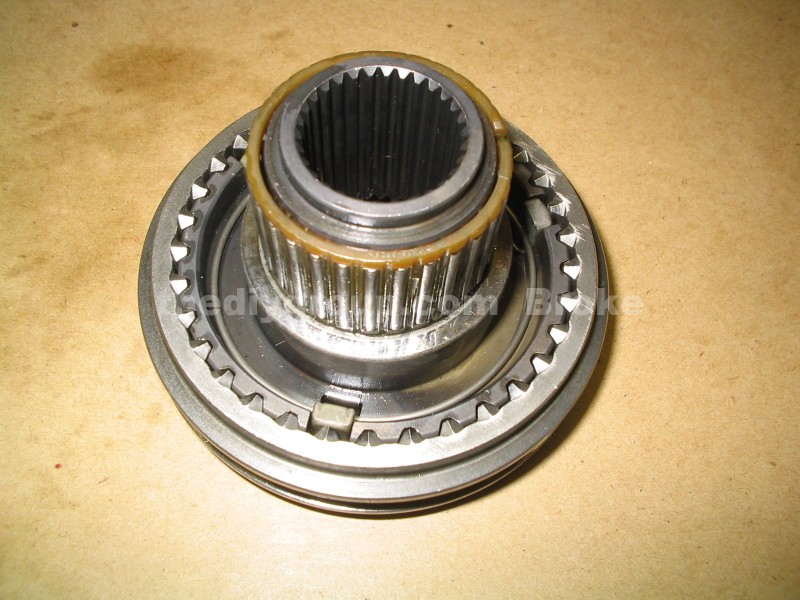

Here is a 5th gear assembly, ready to be installed. the locking clip shown is one used on MK2 16V cars (AGB and 2Y codes) and on MK3 cars up to June 1st, 1997 (AMC, CHE, DFQ codes). It is made for a smaller diameter shaft groove. It won't fit onto an 8V shaft. The 8V shaft uses a circlip, and that fits loose on the 16V shaft.

The 16V/MK3 gear on the output shaft (on the right) has a deep groove shown on top of the gear. This is for the locking clip to engage in. 8V gears do not have this groove, so the clip won't work. This means for those 16V and MK3 cars, no 8V 5th gears can be used in a 5th swap.