CHE 16093

$1100 shipped *sold*

Parts laid out ready for cleaning...

Case insides cleaned out fully, ready to be sealed up in preparation for the blasting work...

Case assembled with all holes sealed with bolts or rubber. It stops most of the sand from getting in, but not all of it. Sand gets anywhere and everywhere. After blasting, the case is rinsed and dried and blown out several times over to make sure everything is clean.

Update 7/01/08

Internal parts cleaned and spread out. They need rinsed and oiled, then assembled...

The case is blasted, but there are a few spots that are still stained, so I am going to sand blast the case one more time.

No pics of the build process, but here is the completed trans. The case was sand blasted, then glass bead blasted. The flanges, release arm, and drain plug were sand blasted, the zinc plated and chromate dipped for corrosion resistance...

The parts that were replaced in the rebuild (pretty much everything but shafts, hubs, gears, and the case); everything is OE VW, or from the OE mfg.'s, unless noted (like the Peloquin bolt kit, or the sync rings form Argentina)...

Bearings

diff taper bearings

output shaft taper bearings

output shaft roller bearing

input shaft ball bearing

input shaft roller bearing

needle bearings for 1-5 gears

TO bearing

Seals

Flange seal kits

input shaft seal

pushrod seal

pushrod bushing

selector seal

release arm seal

green end cap

green seal sleeve

case sealant paste

Syncs

RFI Brazil 1st gear sync ring

Argentina brass sync rings 1-4 gears

sync keys

sync springs

Circlips

4th circlip

3rd circlip

input shaft circlip

2.3mm diff circlips

Misc.

output thrust washer

5th fork plate

5th bolt

Peloquin bolt kit

plastic diff thrust

starter bushing

20mm detent bolt

actuation finger

Teardown 06/19/11

These are the used bearings, there are 2 pics of each race.

The race on the drivers side...

The passenger side diff race...

The small output shaft bearing race...

The large output shaft bearing race, in the retaining plate...

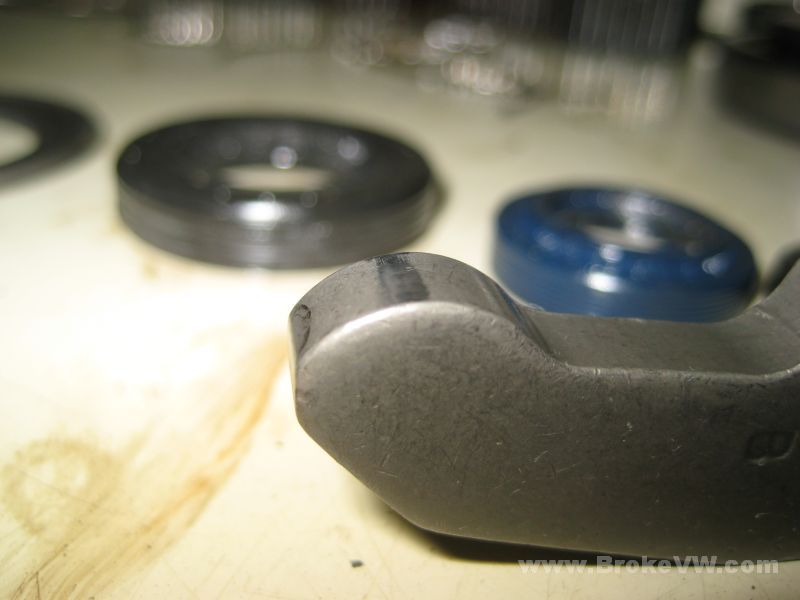

This is the finger out of the rebuilt trans, you asked for new in your email, this is about as close to new as you can get. You can't feel the wear line with your finger, but you can see where it contacted the bearing...

The used reverse idler out of the trans... I am going to look for a better used gear for you, this has a little more wear on the tops of the teeth than I would like to see....

The used ring gear on the diff, bolted in place

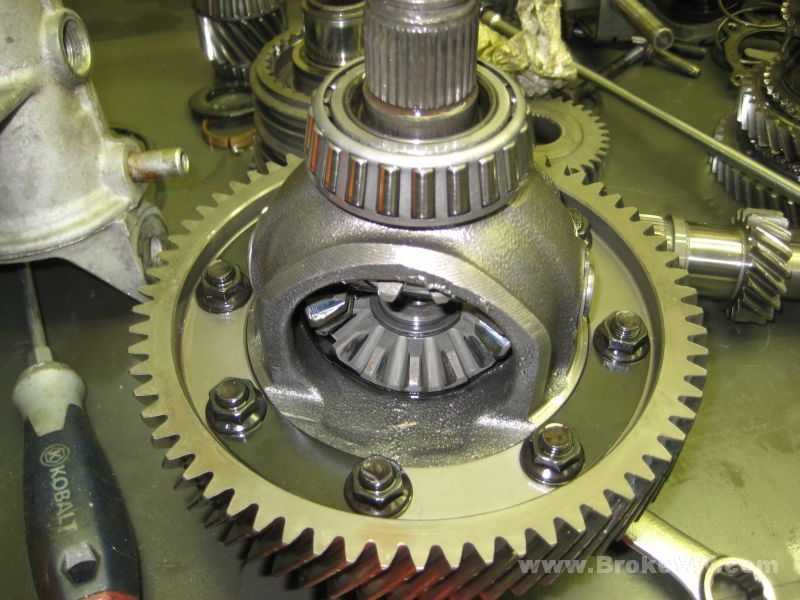

The new 2.3mm clips and the black plastic thrust piece behind the spider gears...

The output shaft...

The good used parts... 5 gear needle bearings, the 2 shaft roller bearings, the input shaft large ball bearing, the 3 sets of sync keys and springs, the circlips (2 for 4th, one for the input shaft, a 3.0mm 3rd), the thrust washer under 1st gear, the input shaft seal, release arm seal, and selector shaft seal. There are also 2 sync rings, the other 3 have been robbed from the trans at some point, so I'd use the 2 used rings on 4th and 5th, new rings on 1st-3rd. The actuation finger is in the lower right corner...

Update 06/21/11

Pics of the new Timken bearings being installed onto the output shaft and the diff carrier...