Peloquin Shim Kit Test

This is a copy of a thread I made on the Vortex...

There must have been bad info floating around about the Peloquin shim kits, because the figure that gets tossed around for the factory percentage is 2%.

This is not correct, and the Peloquin site

states the factory number is 20%.

If stock is 20%, the 40% kit should double

the force required to break the diff loose, and the 80% should offer 4x the

resistance to break free over stock.

I went out tonight and built a diff on the bench, I

used a new one-piece plastic thrust washer, new brass conical rings, and new

2.3mm circlips for the stub axles inside the diff.

I used two bolts on the drive flange, with

my flange compressor tool being used to span the bolts, and this allowed me

to turn the bolt head located in the center and spin the entire flange

without skewing the results.

I measured the diff with no rings on it, just the

2.3mm circlips, and then installed the factory parts, measured again, then

measured the 40% and 80% kit settings.

Nothing = 2.5 - 5 ft-lbs

Factory = 26 - 29 ft-lbs

40% Kit = 77 - 80 ft-lbs

80% Kit = 135 - 140 ft-lbs

The 'nothing' setting is much like a pre-1984 trans, which is missing the conical thrust rings and the springs behind the flanges.

'Factory' is like the standard MK2 trans with the one green seal sleeve sticking out of the passenger side which has the rings and springs.

The springs and cones were added by VW "to locate the shafts free of play" and they did this to stop rattles and noises from the flange area. It was never intended as a 'mini-slip' or any type of traction enhancing device... it was just to stop the parts from making noise. When the car was put on a lift, and one tire spun, and the other spun the same way, and this led mechanics to erroneously think it was a LSD of sorts, but it is not.

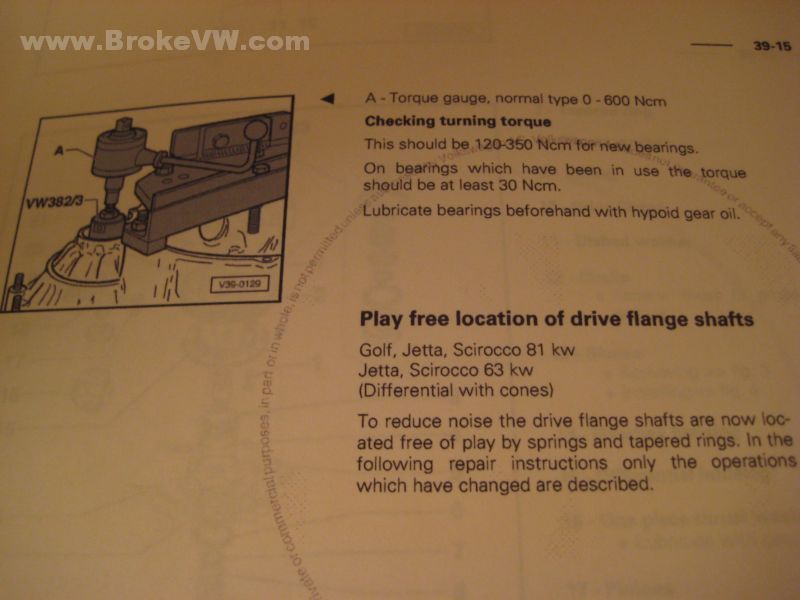

Here is a pic from the factory papers stating the same thing...

Peloquin shim kits involve the use of a 2.25mm-2.30mm washer inserted between the tapered cone and the flange. This shim forces the spring to push harder against the cone, closing the cone up on the output shaft with more force. That is a 40% kit, and then the 80% kit is the same thing, but they use a steel cap with a M10x1.5 bolt that holds the cap in place and threads into the hole in the end of the output shaft, pulling the flange down tighter, compressing the spring more, and adding more force.

Here is a thread from the Scirocco forum on the Vortex where I explain in detail how the shim kit works.... http://forums.vwvortex.com/showthread.php?3016936-The-SheRocco-s-first-tranny-swap&p=35035696&viewfull=1#post35035696

Here are a couple pics, one of the conical thrust ring behind the flange, and the other showing the flange and the spring and cap for the spring.

The test wan't super accurate, but it gives an idea of

what the shim kit does compared to a stock diff with new parts. Many

variables come into play including the condition of the stub axles and the

accuracy of the torque wrench, etc., but the results shouldn't be that far

off.

Click HERE to go back to the Start Page...