Clutch Release Arm Position

The clutch release arm on the outside of the trans should be checked when the clutch pedal drops to the floor and stays there, or suddenly becomes very light and easy to push.

If you can lift the arm up past horizontal, so the arm points to past 9:00 on a clock face as you look at it, then you have a problem further inside the transmission.

If the arm gets solid at the horizontal (9:00) position, then everything inside the trans side should be OK, and you should be looking for a broken clutch cable or a broken pedal cluster.

If you can lift it past horizontal by hand, the finger could be cracked, the TO bearing could be crushed, the pushrod could be broken, the thrust plate could be punctured by the pushrod, or the clutch disk or pressure plates could have failed.

Click here to see how to remove the release arm and finger.

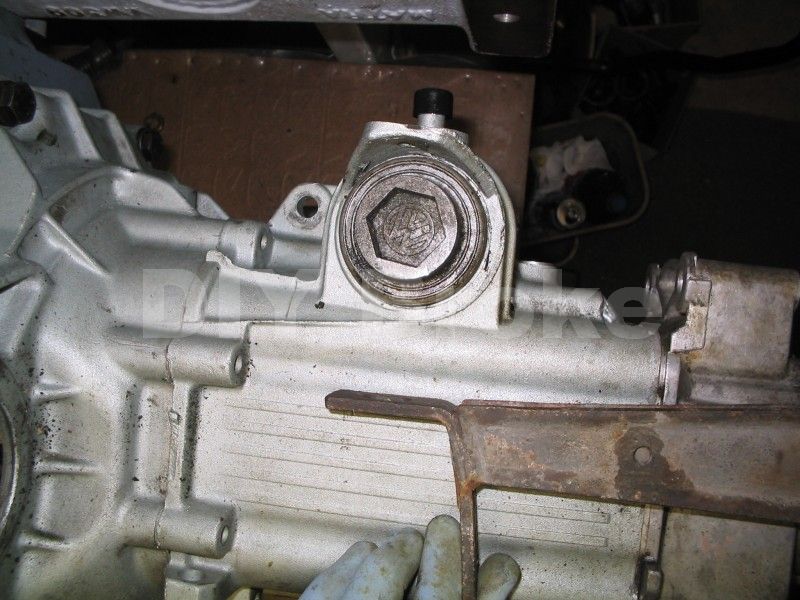

This is where the clutch arm should get solid, as you lift it up by hand...

When the arm is level like this, the actuation finger inside is just contacting the TO bearing, which is just contacting the pushrod, which is shoving the thrust plate, which is starting to collapse the pressure plate finger, and disengage the clutch.

With new parts, the arm will get solid at 9:00, as the clutch disk wears thin, the arm will drop, and start to get solid lower and lower. By the time the arm is as low as about 8:00, the clutch can start slipping, and is worn out.

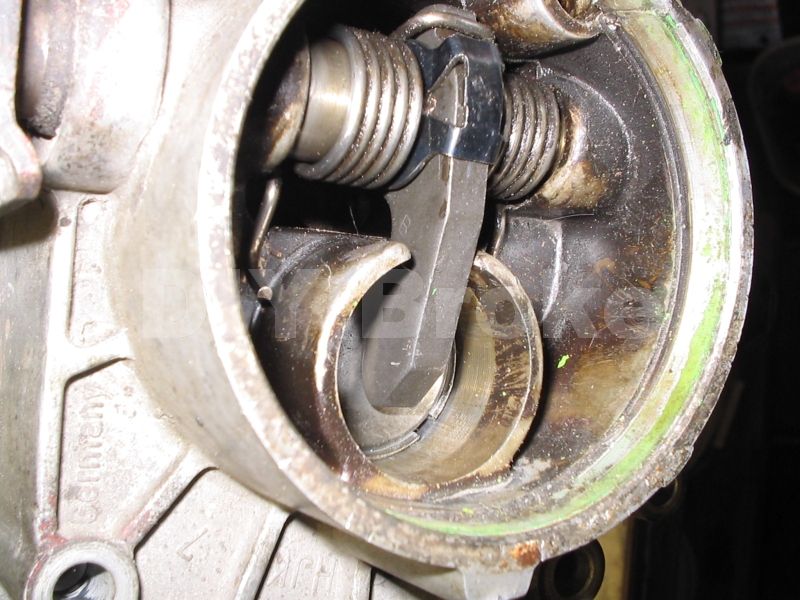

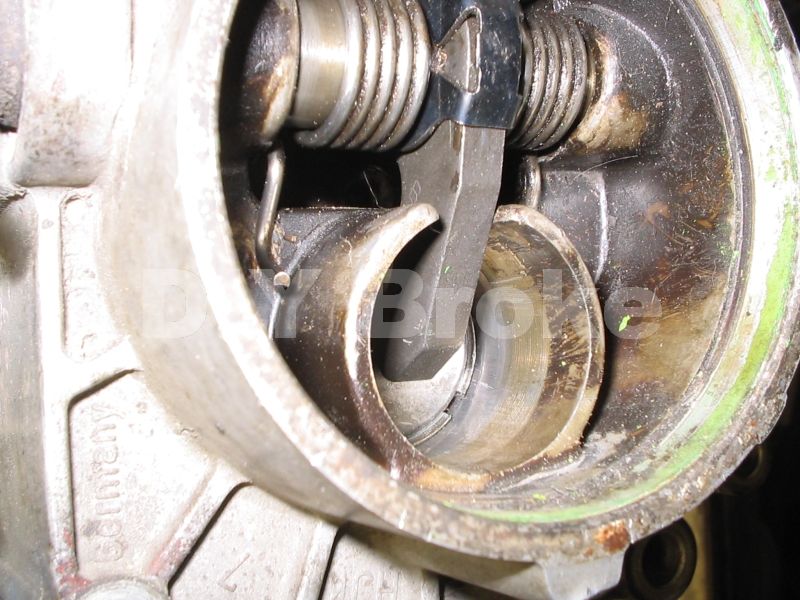

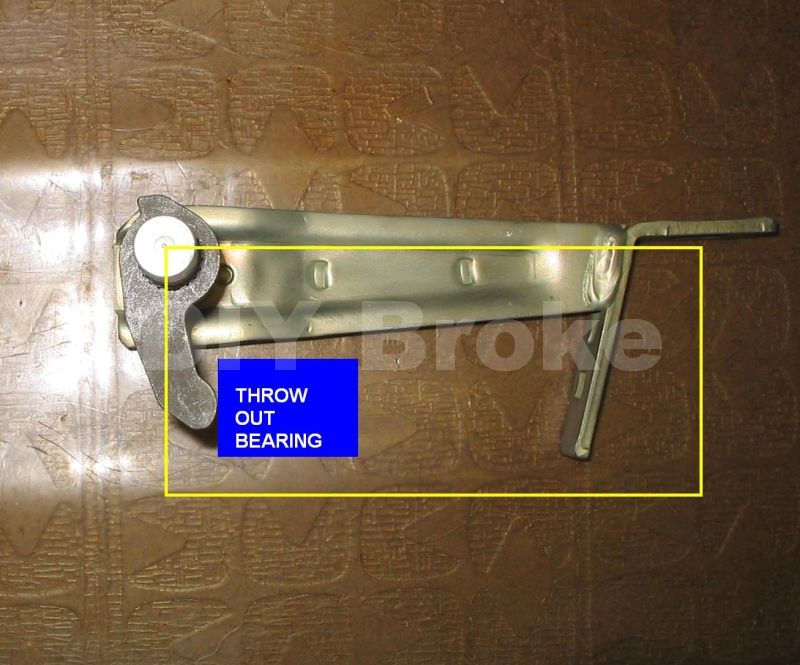

Here is a pic showing the finger coming into contact with the TO bearing when the arm is level...

When the clutch pedal is pressed, the parts all move, and the PP springs are collapsed, and the clutch is disengaged. It takes a lot of movement of your foot to get the leverage needed to allow you to collapse that strong plate.

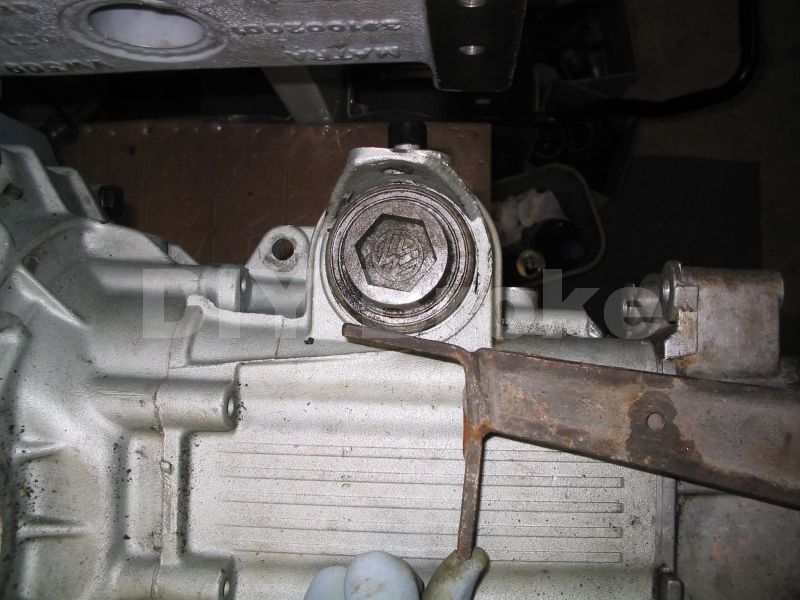

The result is the movement at the trans is not very much at all. It only lifts the arm up about 15 degrees from horizontal, to about 10:00 on a clock face, as shown here (this pic actually shows the arm hitting the threads of the selector cover....normally, that cover is threaded in, and the arm will hit the round portion of the cover instead of the threads. Some trans stop just under the round portion, and don't actually contact the cover at all)....

When the arm is lifted to this spot, the actuation finger will have shoved the TO bearing in, and they'll look like this. You can see the shiny portion of the bearing bore now exposed as the bearing is pushed in. This is all the further the finger will push it...

You can see the TO bearing doesn't move in much at all, the result of all that foot movement is the pushrod and TO bearing moving about 8mm.

The release arm joins to the actuation finger at a 90 degree angle. Even though it looks like the finger is tilted in towards the TO bearing, the contact area is touching the TO bearing at a 90 degree angle.

![]()

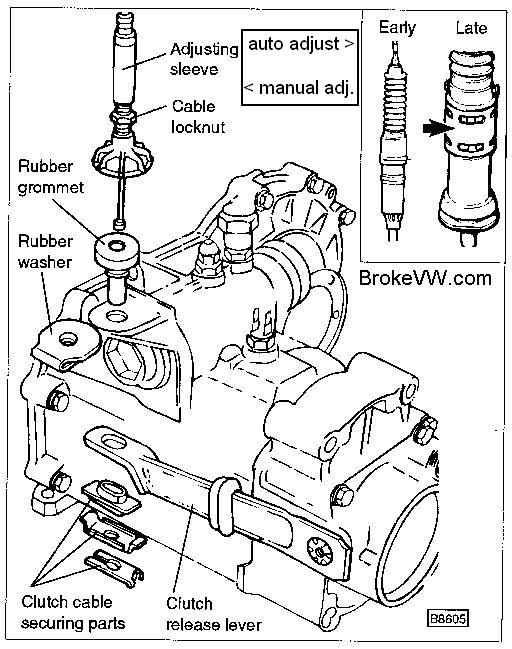

When you have a manual-adjust clutch cable, you want to adjust it so that there is play in the cable. VW specs call for 12mm between the clutch adjusting disk and the trans ledge it sits on. Here is a .mov movie showing the free play being checked by lifting the cable and arm up. You can see the arm get solid when it is level.

Clutch Cable Freeplay Movie On YouTube

This picture shows where the adjustment of the clutch cable free play is measured...

This pic shows how to ID the 2 types of cables used...

On a self-adjust cable, the mechanism will not have any freeplay in the cable, the spring will keep the release arm pulled right up until the parts get solid. To check the self-adjust cable, push down on the arm, and the adjust mechanism should allow the arm to spring down then be pulled back up again.

There is no adjustment for those cables, and if faulty, they should be replaced.

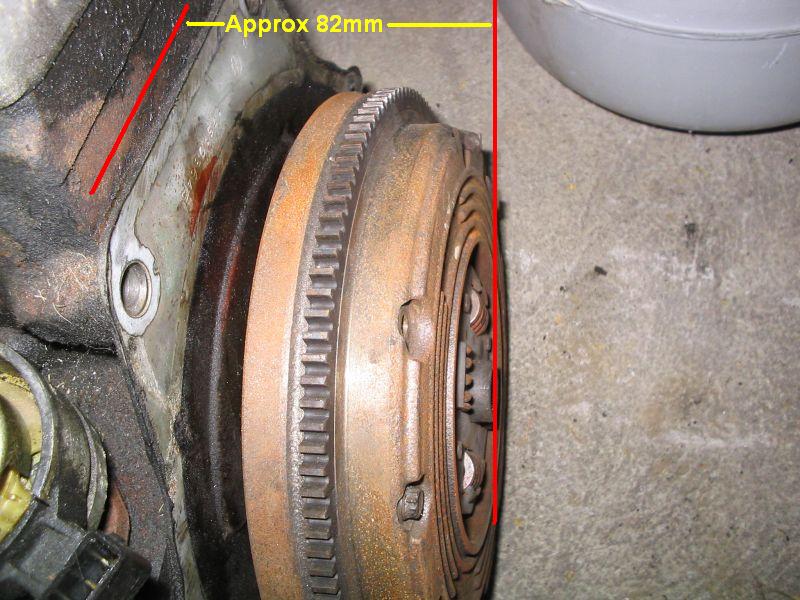

A couple pics showing a worn pushrod sticking out of the end of the input shaft. The measurements are approximate, but will give you an idea of the max amount of movement the pushrod makes.

This pic shows the release arm fully at rest on the black plastic stopper, and the pushrod is extended about 4mm past the input shaft (*note - until I research it more... the last several trans I have checked allow the pushrod to sit about flush with the end of the input, not going along with my earlier research of the pic below, showing 4mm extended)...

This pic shows the release arm lifted up fully, to expose about 24mm of pushrod past the input shaft.

This .gif shows the movement of the release arm during the operation of the pedal. It rests just about 9:00 or horizontal, and as the pedal is pressed, the cable pulls it up as shown. Thanks to tolusina from the Vortex for the use of the .gif image!

Here are a couple of pics showing some measurements I took one day trying to help someone out.... it might help in finding out of the clutch parts are installed right and in the right spot for the pushrod to properly disengage the clutch if you are having problems with the clutch not disengaging....

The pushrod should be about 340mm long, or 13-3/8"

Some more pics of other measurements:

The measurements are all approximate and might not match what you find with your parts, and some things like the piece of sheet metal between the engine and trans must be accounted for if you start to calculate where the parts are in relation to each other.